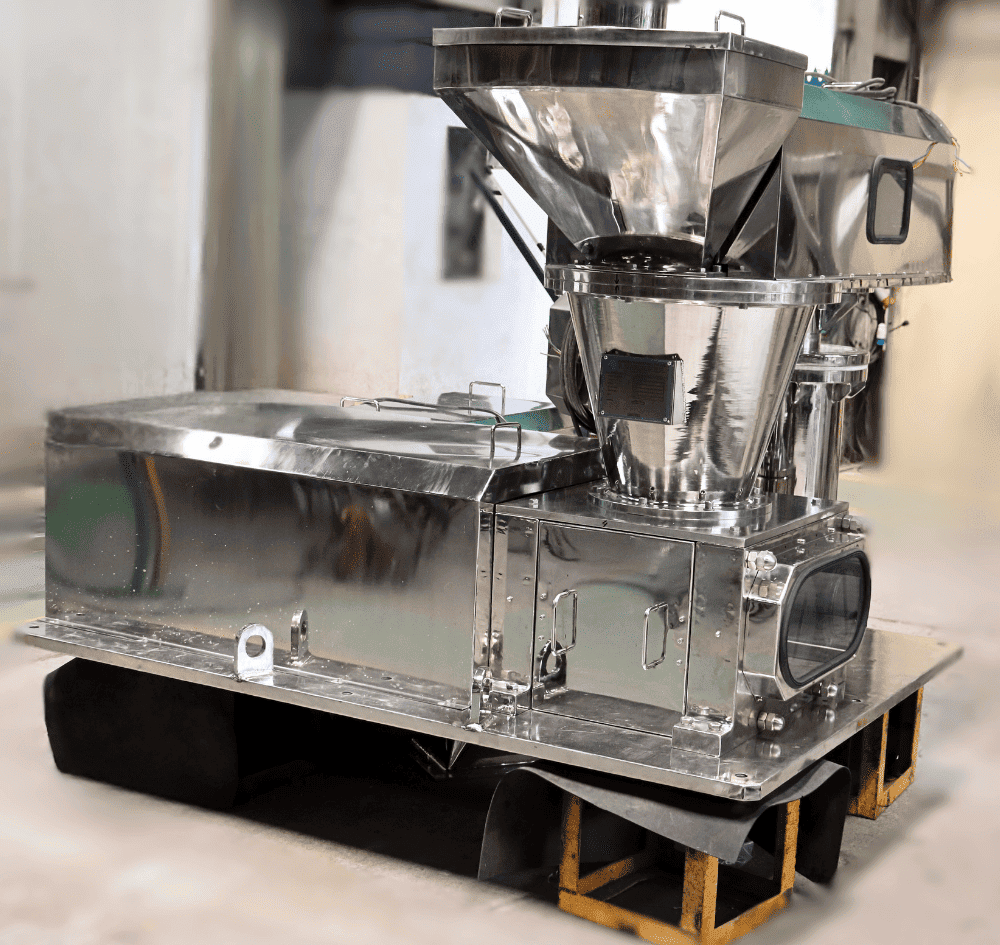

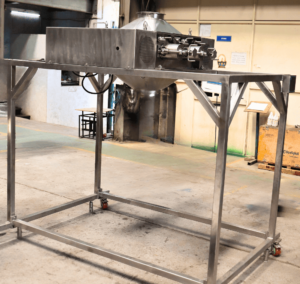

Roll Compactor Machine

Manufacturer of Roller Compactor

Roll compactor machines are used in the dry granulation process. They compress the input material into granules of the desired size. We are leading roll compactor machine manufacturers and suppliers for the food, foundry, and pharma industries, helping to increase bulk density, reduce dissolution rates, and handle explosive products all while delivering world-class industrial standards for more than 20 years. We are an ISO 9001:2015-certified company, and all our roll compactor machines are manufactured to international standards. We are a trusted roller compactor machine supplier to many reputed industries in and around Pune. We also supply our roll compactors customized as per your project requirements.

Padmatech Industries specializes in the design and development of roll compactor equipment, known for exceptional performance and reliable operation. These machines play a vital role in industries such as pharmaceuticals, chemicals, food processing, and metallurgy, where they are used to convert powders into granules. Our roll compactors are engineered to meet the highest standards of efficiency, quality, and precision.

How Roll Compactor Machines Work

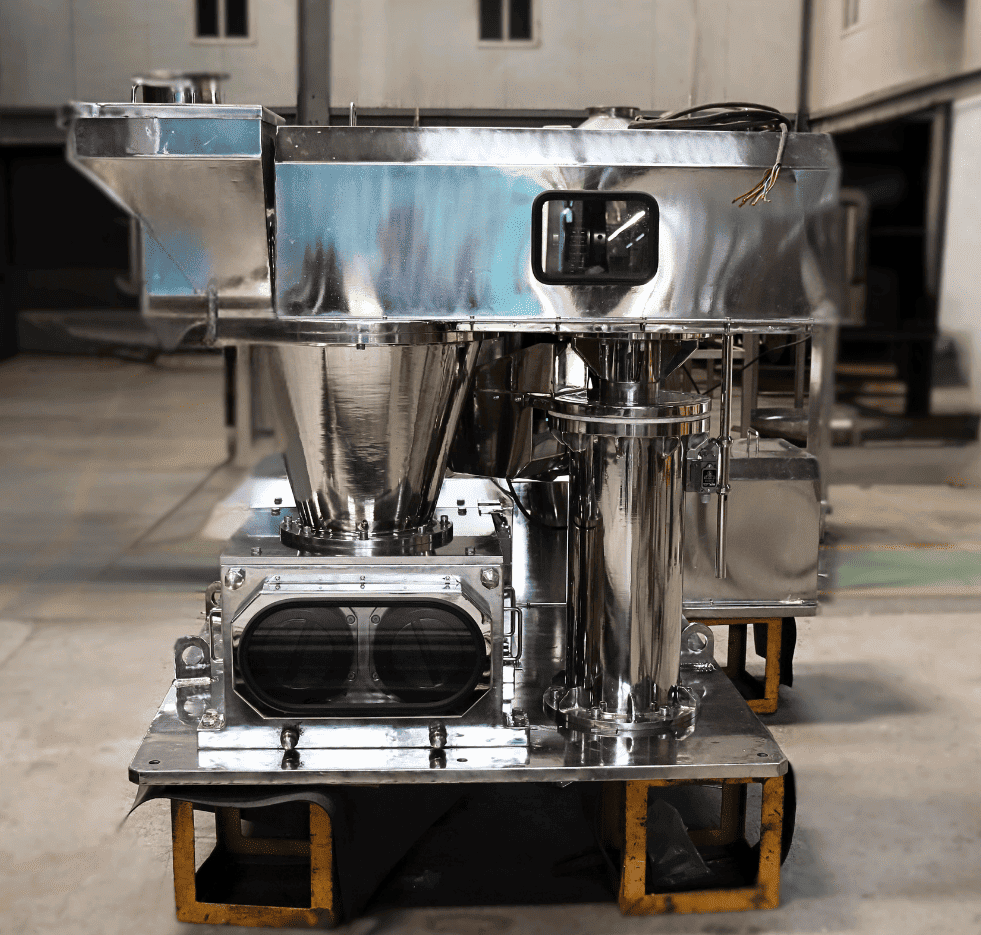

Roll compactor machine work on the guideline of dry granulation, where powders are compressed between two counter-rotating rollers to create thick sheets or flakes. These sheets are then broken down into granules of a wanted size using a granulator. This process kills the need for binders or solvents, making it perfect for moisture-sensitive materials and guaranteeing a steady, uniform product.

Design and Development of Compactor Machine

Applications of Roll Compactor

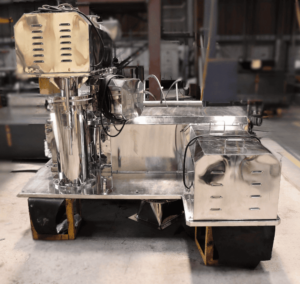

1. Pharmaceuticals: In the pharmaceutical industry, our roll compactor machines are utilized to create granules from active pharmaceutical ingredients, improving flow properties and compressibility for tablet production.

2. Chemicals: For the chemical industry, our machines compact fine powders into granules, improving product handling, decreasing dust, and progressing material flow in consequent preparation steps.

3. Food Processing: In the food processing industry, our roll compactors are used to create granules from powders, for example, instant drink mixtures, herbs and spices, and dietary supplements, assuring reliable quality and ease of processing.

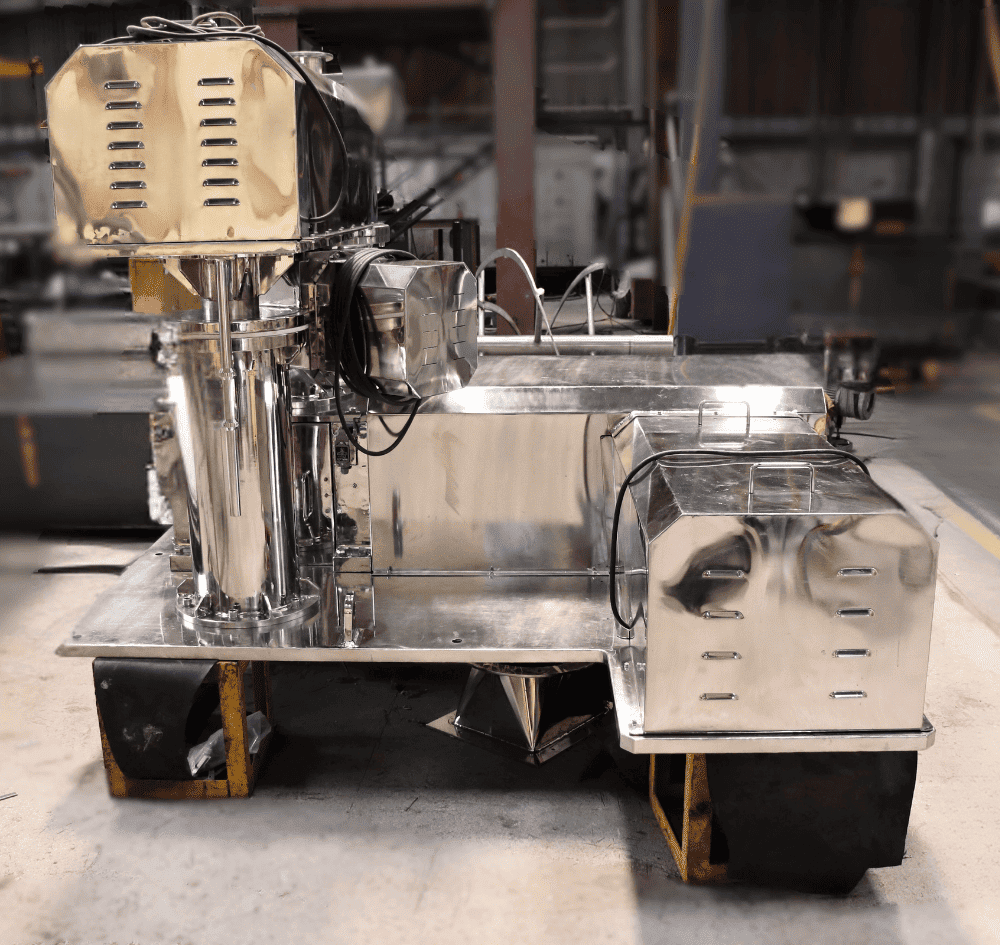

Advantages of Our Roll Compactor Machine

Roller compactor machines from Padmatech Businesses offer a few focal points that set them apart:

Effective Dry Granulation: Our machines perform efficient dry granulation, eliminating the need for wetting agents and drying steps, hence diminishing production time and costs.

High Throughput: Built for high throughput, our roll compacting machines can handle large volumes of material quickly.

Granule Size: Advanced technology provides accurate pressure and required roller speed, resulting in precise granule size and depth, which is significant for keeping up item quality.

Energy Proficiency: Our equipment is designed in a way that optimizes energy consumption, decreases operational costs while increasing productivity.

User-Friendly Design: Our machines have simple controls and maintenance features so that these roll compactors can be user-friendly.

Enhance Your Production Process with Roller Compactor Machine

Roll compactor machines designed by Padmatech Industries are the epitome of unwavering quality, efficiency, and accuracy in compaction. Our devotion to high-quality equipment, great control systems, and versatile applications guarantee that our equipment meets the needs of different sectors. By choosing Padmatech, businesses can improve their production processes, improve product quality, and accomplish more noteworthy operational productivity.

-

Product Features of Roll Compactor

-

Product Specifications of Roll Compactor

-

Dust free operation

Dust free operation -

Rolls without any slippage or leakage

Rolls without any slippage or leakage -

Easy cleaning

Easy cleaning -

Low maintenance

Low maintenance -

High quality material

High quality material -

With torque limiters

With torque limiters -

Special safety feature

Special safety feature

Capacity

100 to 1000 KG/ Hour

Material of Construction

SS 316, SS 304, SS 410

Dimensions

Depends Upon Capacity

Warranty

1 year

Contact Padmatech Industries for world-class process equipment to boost your business & productivity.

Contact Padmatech Industries for world-class process equipment to boost your business & productivity.