Quench Tank

Quench Tank Manufacturer

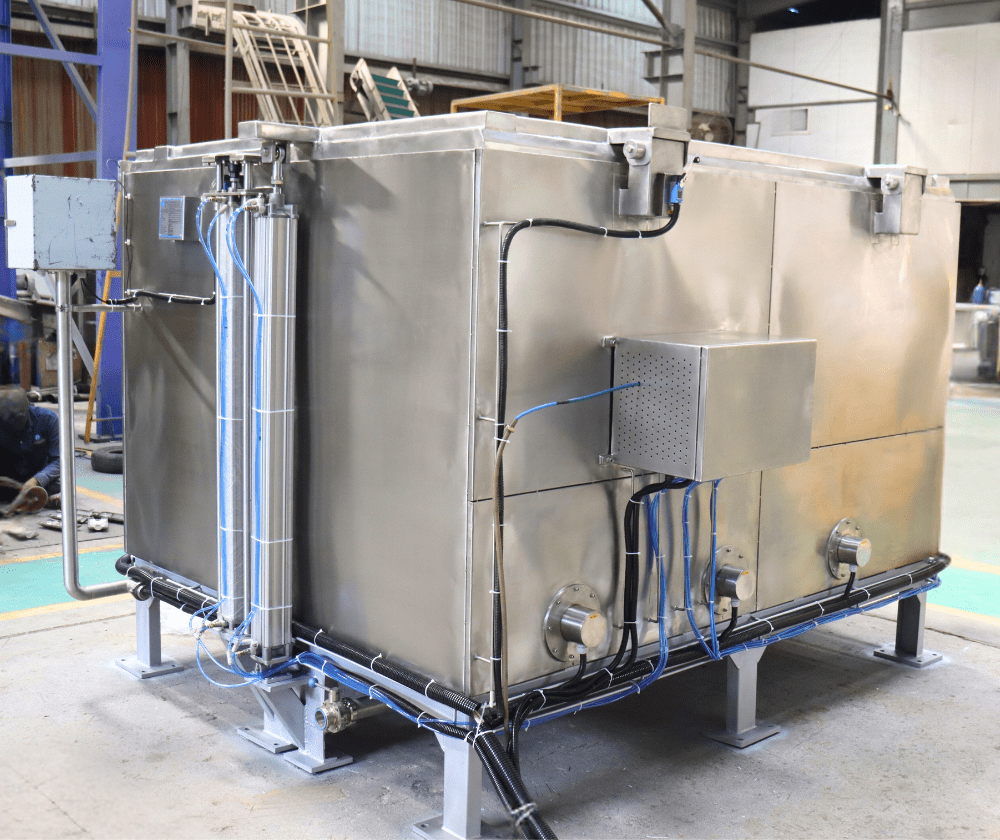

Quenching is the rapid cooling of a workpiece in water, oil, or air to strengthen and harden materials like steel and other iron-based alloys. Padmatech Industries has years of experience in designing and manufacturing custom quench tanks based on process requirements, charge size, and weight. We use standard materials to ensure a smooth quenching heat-treatment process. As an ISO 9001:2015 certified company, we manufacture all quench tanks from high-quality raw materials. With over 20 years of expertise, we are a leading manufacturer of quench tanks, offering customized solutions for industrial quenching needs.

Explore Our Wide Range of Quench Tanks

-

Industrial Quenching Tank

Industrial Quenching Tank -

Quench Water Cooler

Quench Water Cooler -

Water Quench Tank

Water Quench Tank -

Multiple-Section Quench Tank

Multiple-Section Quench Tank -

Horizontal & Vertical Quench Tank

Horizontal & Vertical Quench Tank

Padmatech Industries offers a state-of-the-art quench tank designed to meet the stringent requirements of modern industrial processes. Quenching tanks are critical in heat treatment applications because they rapidly cool heated metals to achieve desired material properties such as hardness and strength. Our quenching tanks are designed for efficiency, reliability, and accuracy, ensuring optimal performance in various industrial environments.

Quenching Tank Construction for Durability and Performance

Our quenching tank is constructed of durable materials to withstand extreme heat treatment conditions. These tanks are usually made of high-quality stainless steel and are highly resistant to corrosion and high temperatures. Our tanks are designed with strong materials to ensure reliability and longevity even with continuous harsh industrial use.

Cooling Mechanism in Quench Tanks

The quenching process rapidly cools hot metal parts by immersing them in a cooling medium like water, oil, or specialized polymer solutions. Our quench tank features advanced cooling systems that ensure even temperature distribution throughout the tank.

This precise control is essential for achieving the desired metallurgical properties while preventing defects like deformation or cracking.

Quench Tank Uses in Various Industries

Aerospace:

The aerospace industry uses our quench tank to treat components such as turbine blades and structural parts to ensure they meet the quality standards and required strength.

Metallurgy:

Our quenching tanks are used to quench and harden steel and other alloys, improving their structural integrity for construction and manufacturing processes.

Automotive:

In the automotive industry, our quenching tanks are essential for the heat treatment of gears, crankshafts, and other critical components, improving their wear resistance and performance.

Oil and Gas:

In the oil and gas industry, our quench tanks are used to heat-treat critical components like drilling tools, pipelines, and valves. This process enhances their strength, wear resistance, and durability, ensuring reliable performance in extreme conditions.

Energy Efficiency Quench Tanks

Our quenching tank is designed with energy efficiency in mind. Advanced insulation materials and efficient cooling systems reduce energy consumption, lower operating costs, and maintain high cooling efficiency.

This focus on energy efficiency supports sustainable industrial practices and helps our clients to achieve their goals.

Enhance Heat Treatment Processes With Our Quench Tank

Quenching tanks from Padmatech Industries provide advanced cooling solutions required to achieve the desired mechanical properties of heat-treated metals. Thanks to its robust structure, precise cooling mechanism, and energy-efficient design, our quenching tank ensures reliable performance in various industrial applications. By choosing Padmatech Industries, companies can improve their heat treatment processes, improve product quality, and support sustainable production methods.

-

Product Features of Quench Tank

-

Product Specifications of Quench Tank

-

Customized Design

Customized Design -

Powerful Circulation

Powerful Circulation -

Long life and trouble free operations

Long life and trouble free operations -

Energy Efficient

Energy Efficient -

Robust Construction

Robust Construction

Capacity

As per Customer Requirement

Material of Construction

SS 304, SS 316

Dimensions

Customized

Warranty

1 Year

Contact Padmatech Industries for world-class process equipment to boost your business & productivity.

Contact Padmatech Industries for world-class process equipment to boost your business & productivity.