Distillation Column

Distillation Column Manufacture

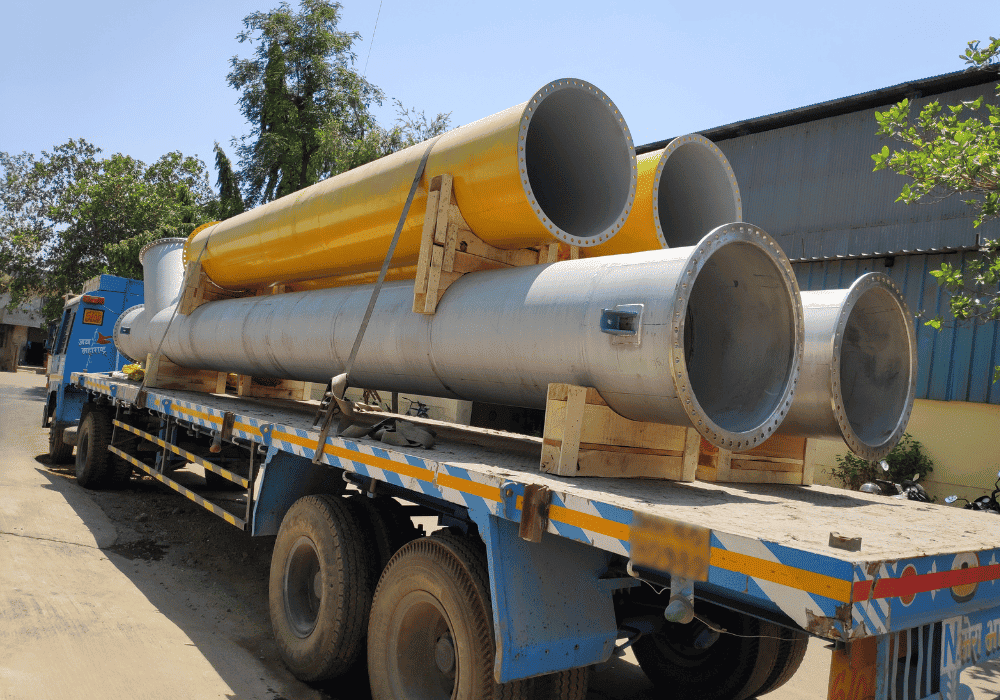

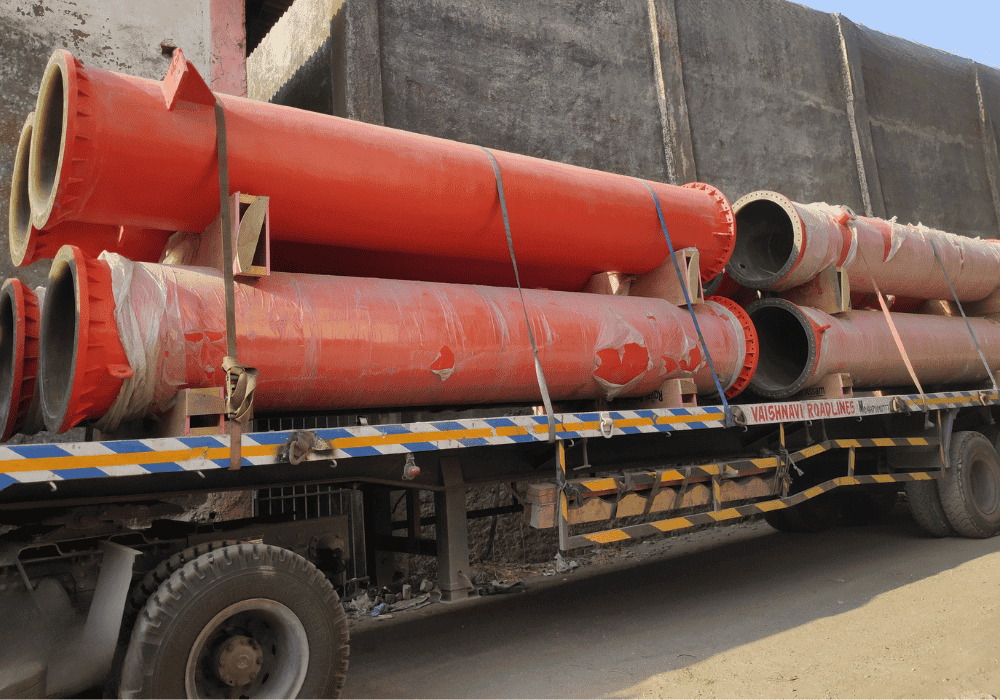

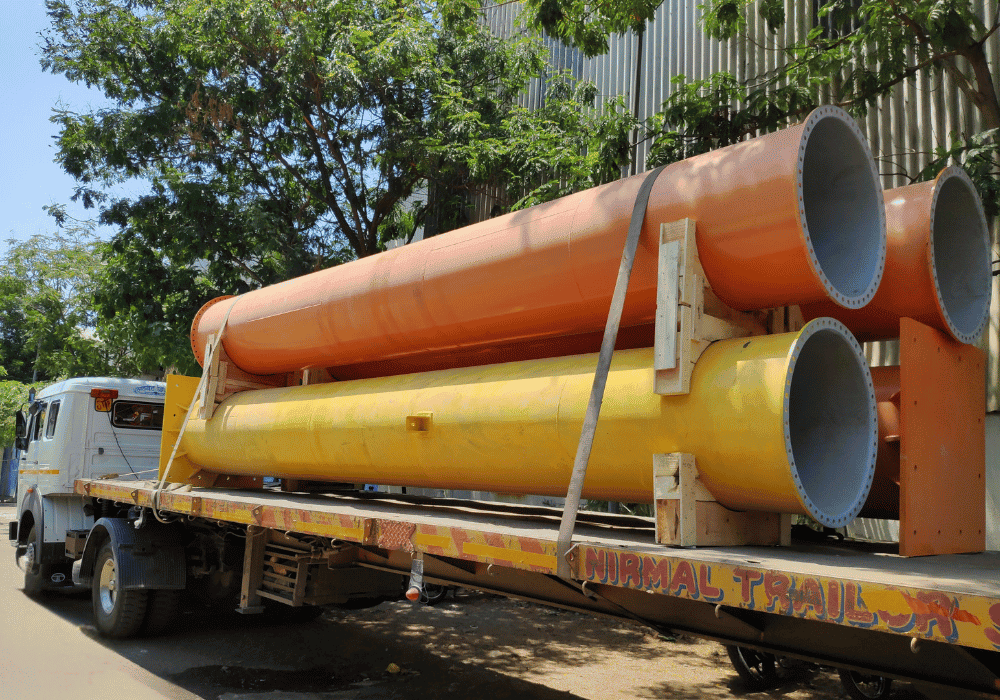

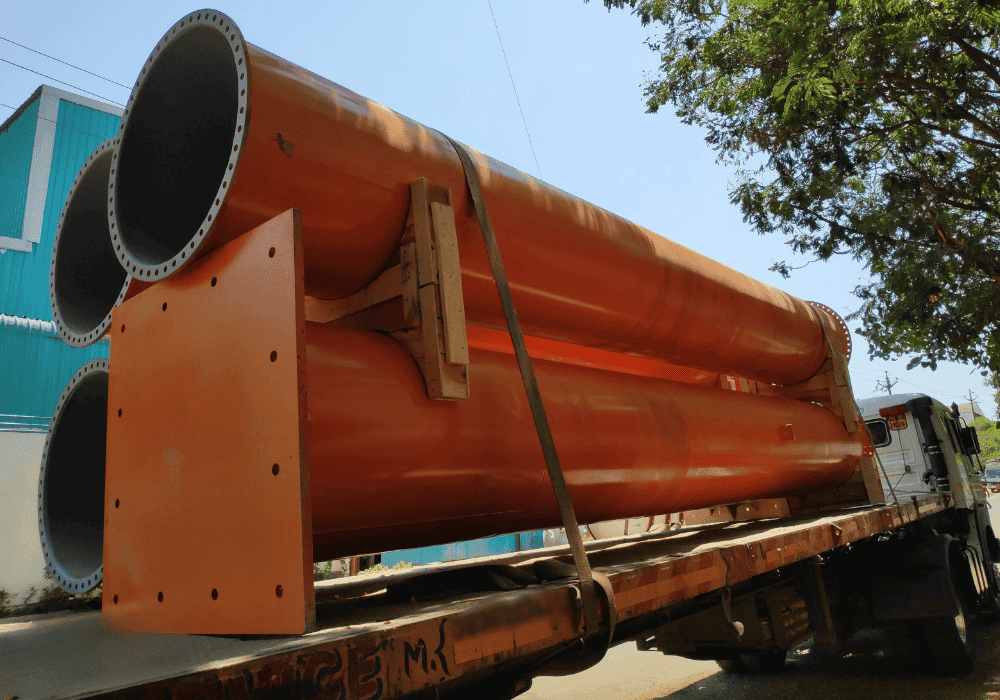

The process of separating a mixture into its components or fractions is known as distillation. A distillation column is an instrument that carries out this process efficiently. Padmatech Industries has been a leading distillation column manufacturer in india for more than 20 years. We have experienced and professional designers who deliver quality distillation column designs as per your project requirements. We have successfully installed fully functional distillation towers and industrial distillation columns across various industries.

Recently, we successfully manufactured and supplied SS 316 stainless steel distillation columns for the pharmaceutical industry. Till now, we have manufactured and delivered more than 1,000 distillation columns of various sizes for projects across India and globally. Our team is always ready to take on complex challenges and provide practical solutions through in-house design, manufacturing, supply, installation, and commissioning of advanced systems across India

Types of Distillation Columns We Offer

We are also pioneers in manufacturing and supplying packed columns, fractionating columns, rectification columns, Stainless steel distillation columns and more. Many of our clients rely on us for their industrial distillation needs. We have supplied distillation columns to several esteemed clients for crude oil distillation as well. As an ISO 9001:2015 certified company, we also serve a strong international customer base, meeting their requirements as a trusted exporter of industrial distillation columns.

Principle of Operation in Distillation Column

We take pride in offering high-quality distillation columns and essential equipment for the separation and purification of chemical mixtures. Distillation columns operate on the principle of separating components based on differences in their boiling points, making them indispensable in industries such as petrochemicals, pharmaceuticals, food and beverage, and environmental management.

Application of Distillation Columns

Our distillation columns are designed to handle multiple applications.

Petrochemical Industry: They play a key role in refining crude oil into valuable products such as gasoline, diesel, and jet fuel.

Pharmaceuticals Industry: They are used for the purification of active ingredients and solvents.

Food and Beverage Industry: Relies on distillation columns for processes such as alcohol distillation and the concentration of flavors and fragrances.

Environmental Management: Applications include solvent recovery, recycling, and the treatment of industrial wastewater.

Understanding the Working of a Distillation Column

The efficiency of our distillation column is driven by advanced design and precise control systems. The process begins with heating the mixture in a reboiler, causing it to vaporize. The vapour then rises through the column, which is packed with trays or structured packing designed to enhance contact between the vapour and liquid phases. As the vapour ascends, components with higher boiling points condense back into liquid and are collected as distillate, while lower boiling point components continue rising until they are collected at the top.

Padmatech Industries’ distillation columns are renowned for their durability and consistent quality. Constructed from high-grade materials such as stainless steel, our columns are built to withstand high temperatures, corrosive environments, and the demands of continuous operation. Our columns are additionally furnished with sophisticated control frameworks that consider exact monitoring and adjustment of parameters, guaranteeing ideal separation efficiency and product purity.

Energy Efficiency in Distillation Columns

Energy efficiency is a critical component of our distillation columns. By upgrading heat combinations and using advanced protective materials, we limit energy utilization and reduce operational expenses. This upgrades monetary effectiveness as well as aligns with maintainability objectives by bringing down the ecological impression of the distillation process.

Conclusion of Distillation Column

Padmatech Industries is committed to delivering the best distillation columns in India, recognized for their superior design, durability, and efficiency. Whether you need a fractional distillation column, packed column, or a complete industrial distillation system, we provide end-to-end solutions. By choosing Padmatech, you partner with a trusted distillation column manufacturer that ensures innovation, cost-effectiveness, and long-term reliability.

-

Product Features

-

Product Specifications

-

Quality Material

Quality Material -

Rugged Design

Rugged Design -

Low maintenance cost

Low maintenance cost -

Highly Durable

Highly Durable -

High Grade and Effective packing material

High Grade and Effective packing material -

Use Advance Technology for Vacuum Application

Use Advance Technology for Vacuum Application

Capacity

100 Ltr to 50000 Ltr per batch / hour

Material of Construction

SS 304, SS 316, Exotic Alloys

Warranty

1 year

Contact Padmatech Industries for world-class process equipment to boost your business & productivity.

Contact Padmatech Industries for world-class process equipment to boost your business & productivity.