Paddle Blenders

Paddle Blenders

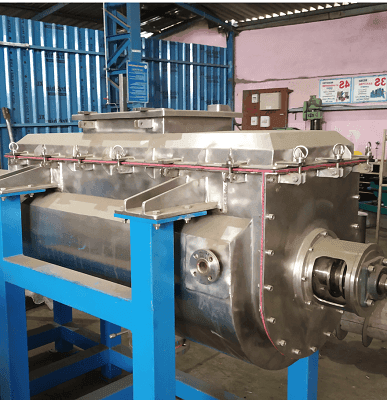

Dispersion of individual particles into liquids requires blenders to force agitators through stationery material. Paddle blender is special purpose equipments used to accelerate process of dispersion. Padmatech Industries are leading paddle blender manufacturer assuring best and fine quality outputs.

All our paddle blenders are best suited for variety of industrial process such as feed and grain, non-directional liquid or slurry mixes, soap pellets, particulates, abrasive products, pastes, filter cakes fragile/friable products etc.

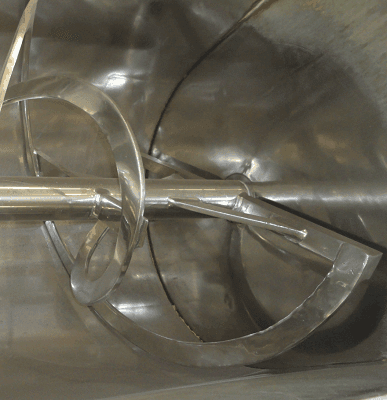

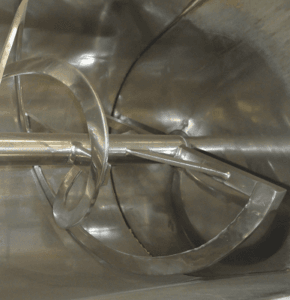

Our paddle blenders are consists of centrally mounted horizontal shaft, a cylindrical container, paddles, plough or other shaped mixing elements special openings at the top and a complete drive unit. Team of skilled professionals working with us for many years enabled us to deliver variety of quality blending equipments tailoring to your project needs.

All our paddle blenders are best suited for variety of industrial process such as feed and grain, non-directional liquid or slurry mixes, soap pellets, particulates, abrasive products, pastes, filter cakes fragile/friable products etc.

Our paddle blenders are consists of centrally mounted horizontal shaft, a cylindrical container, paddles, plough or other shaped mixing elements special openings at the top and a complete drive unit. Team of skilled professionals working with us for many years enabled us to deliver variety of quality blending equipments tailoring to your project needs.

We are ISO 9001:2015 certified company and thus all our paddle blenders are design in accordance with international standards. We are also market leaders for manufacturing and supplying the following types of equipment:

-

Paddle mixer

-

Paddle stirrer

-

Powder blender

-

Industrial paddle mixer

-

Double paddle mixer

Paddle Blender: Efficient Blending Solution

A paddle blender is a very versatile blending equipment used in industries such as pharmaceutical, food, chemical, and others. Recognized for its robust construction and performance, the paddle blender is designed to handle a wide range of materials from powders and granules to pastes and slurries.

Design & function

The main component is its horizontal cylindrical mixing chamber equipped with rotating blades. These are placed to ensure thorough mixing of the ingredients. The blades are crucial; they are usually flat and wide, allowing them to effectively push and pull materials through the mixing chamber, promoting efficient mixing.

Using a paddle blender is very easy. The materials to be blended are loaded into the mixing chamber and the blades are set in motion. Then they lift and blend the materials, creating a gentle and thorough mixing. This mixing is especially useful when working with sensitive materials that can be damaged by aggressive mixing.

Using a paddle blender is very easy. The materials to be blended are loaded into the mixing chamber and the blades are set in motion. Then they lift and blend the materials, creating a gentle and thorough mixing. This mixing is especially useful when working with sensitive materials that can be damaged by aggressive mixing.

Advantages of a paddle blender

Paddle blenders have many advantages that make them a good choice for industrial mixing. Paddle blenders can handle a variety of materials, making them suitable for a variety of applications in various industries. Whether you’re mixing dry flour, wet ingredients, or even viscous dough, a blender can produce consistent results.

Another advantage of paddle blenders is their efficiency. The design of the paddle ensures fast and even mixing of materials, which decreases mixing times and increases efficiency. This efficiency is further enhanced by the blade configuration to meet mixing requirements.

Unlike more aggressive mixers, which can generate heat and potentially break down, our paddle mixers operate with low shear force. This makes them ideal for mixing applications where product integrity is important, like in the pharmaceutical or food industry.

Another advantage of paddle blenders is their efficiency. The design of the paddle ensures fast and even mixing of materials, which decreases mixing times and increases efficiency. This efficiency is further enhanced by the blade configuration to meet mixing requirements.

Unlike more aggressive mixers, which can generate heat and potentially break down, our paddle mixers operate with low shear force. This makes them ideal for mixing applications where product integrity is important, like in the pharmaceutical or food industry.

Applications

Paddle blenders are used in the drug industry to blend active ingredients. Their blending process makes sure that sensitive APIs are not harmed during the process.

In the food sector, blenders are used to blend ingredients, from dry spices to wet doughs and batters. This makes them an excellent tool to produce consistent and high-quality products.

The chemical industry also benefits from the use of blenders. They are used to mix chemicals, polymers, and other materials, ensuring the homogeneity and composition of the final product. The versatility of paddle blenders allows them to be used in a wide range of chemical processes, from simple mixing to complex formulations.

In the food sector, blenders are used to blend ingredients, from dry spices to wet doughs and batters. This makes them an excellent tool to produce consistent and high-quality products.

The chemical industry also benefits from the use of blenders. They are used to mix chemicals, polymers, and other materials, ensuring the homogeneity and composition of the final product. The versatility of paddle blenders allows them to be used in a wide range of chemical processes, from simple mixing to complex formulations.

Conclusion

Our paddle blenders are irreplaceable equipment for any industry that requires efficient, versatile, and gentle mixing solutions. Their robust design, ability to handle a variety of materials, and gentle mixing make them an invaluable tool for achieving consistent, high-quality results. Whether in the pharmaceutical, food, or chemical industries, paddle blenders are still the first choice for industrial mixing applications.

Product Features

-

Short Mixing Time

-

High throughput

-

Economic operations

-

Easy cleaning

-

Low Maintenance

-

High Quality Material

Contact Padmatech Industries for world-class equipment to boost your business & productivity.

Contact Padmatech Industries for world-class equipment to boost your business & productivity.