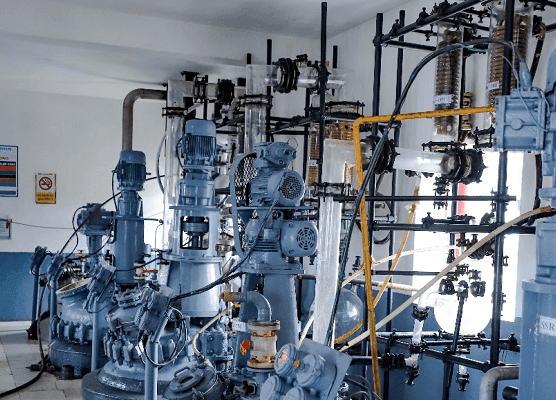

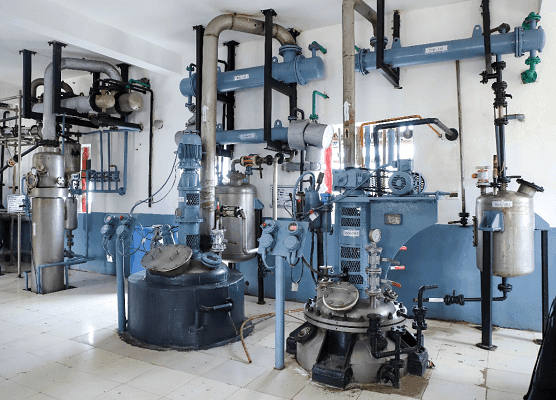

API Plant

Chemical plant requires specialized equipment, units, and technology in the manufacturing process. We are a leading chemical equipment manufacturer (API) based in Pune and offer our quality manufacturing services at the Pan India level. Padmatech Industries is known for delivering EPC projects i.e. from design to construction to installation thus avoiding the hassle of customers managing their products from many places.

Active Pharmaceutical Ingredients (API) Pharmaceutical Plants also same technologies that have similarities to chemical plant technology such as fluid systems and chemical reactor systems. We are a well-known manufacturer of Active Pharmaceutical Ingredients (API)pharmaceutical machinery in India. We are pioneers in setting up an Active Pharmaceutical Ingredients (API) chemical plant and thus provide our clients a full-service experience, from initial design and conception right through to the installation team unveiling the finished product. We are ISO 9001:2015 certified company and thus follow international quality standards in all our operations.

We have a great customer base for many years for chemical plant equipment manufacturer service as we provide customization to each piece of equipment as per project requirements. Based on our experience and highly qualified workforce, we are reputed Active Pharmaceutical Ingredients (API) pharma machinery manufacturers in India. We have developed best-in-class manufacturing plants to deliver equipment on time with the best quality.

Padmatech workforce is a pioneer in Active Pharmaceutical Ingredients (API) pharmaceutical equipment design releasing heavy burdens on you on this front. From Design to Installation, we provide all types of services required to set up any kind of industrial plant. We are always focused to provide the best technology and universal standard to our client Active Pharmaceutical Ingredients (API) pharmaceutical manufacturing equipment suppliers making equipment deliveries directly to your plant site.

Advanced Engineering Solutions for API Plant Design

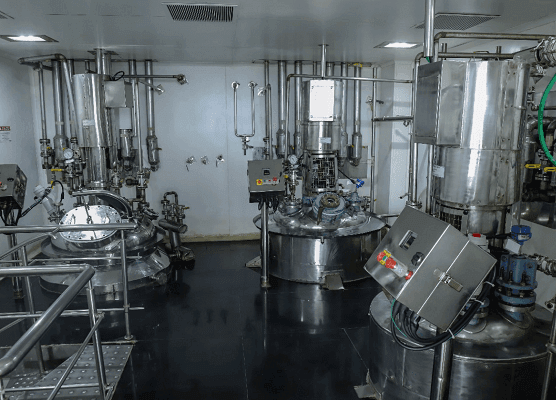

Quality Materials Used in API Plant Construction

Padmatech Industries prioritizes the use of quality materials. Our factory is built with corrosion-resistant materials such as stainless steel and other alloys for durability and long life. The construction process follows the best industry standards, which guarantee that the facilities can withstand the requirements of chemical and pharmaceutical production.

Innovative Process Solutions for Enhanced API Plant Production

Compliance and Safety in API Plant

Durability & Operational Performance

Custom Design Solutions for Every API Plant

Why Us for API Plant

-

Manufacturers and Suppliers of Chemical and Pharmaceutical Projects

Manufacturers and Suppliers of Chemical and Pharmaceutical Projects -

Pioneers in EPC (Engineering, Procurement and Construction) Projects

Pioneers in EPC (Engineering, Procurement and Construction) Projects -

Best design solutions

Best design solutions -

Energy efficient plants

Energy efficient plants -

Easy customization provided for all kinds of requirements

Easy customization provided for all kinds of requirements