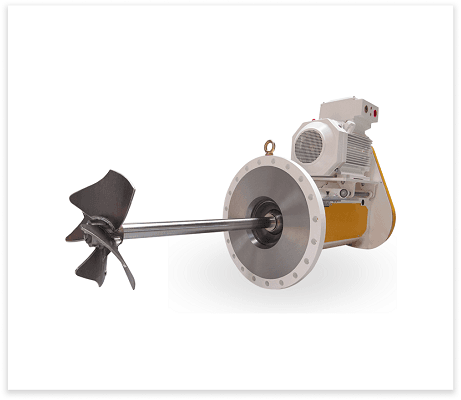

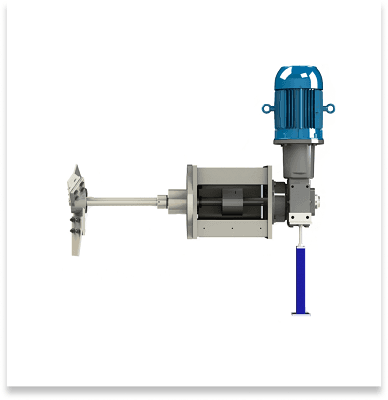

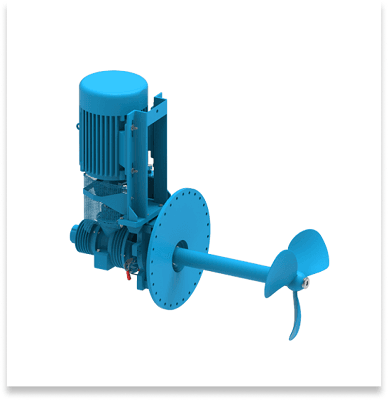

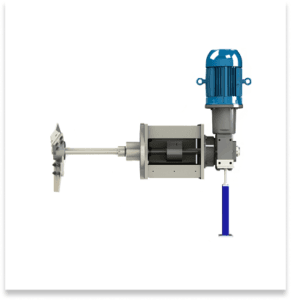

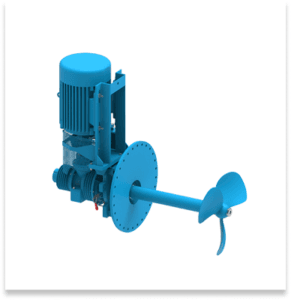

Bottom Side Entry Mixer

Bottom Side Entry Mixer

The bottom entry mixer is commonly used in conjunction with a slow-speed anchor stirrer or scraper unit for high-viscosity products.Industries like Agriculture, Pharmaceutical, Chemical, Cosmetics, Bio-diesel, Food, etc. Need a bottom entry mixer or side entry mixer for their industrial process. Padmatech Industries is the leading manufacturer of bottom-entry mixers.These instruments are mainly used for liquid and powder mixing purposes. We offer cost-effective and energy-efficient solutions with our liquid and powder mixing equipment.

We are trusted suppliers of bottom entry mixers and provide the following various instruments:

Types of various Instruments

• Impeller side entry mixer

• Crude side entry mixer

• Side entry agitator

• High shear bottom entry mixer

• Homogenizer bottom entry mixer

• Bottom entry agitator

• Industrial bottom mixer

• Industrial side entry mixer

The Manufacture

Applications

Our bottom-side entry mixer equipment is versatile and suitable for many industries.

Pharmaceuticals:

Used to mix creams, oils and high-viscosity suspensions to ensure consistency and uniformity of product formulation.

Chemicals:

useful for preparing emulsions, dispersions, and solutions, to facilitate the mixing of various chemicals.

Food processing:

Used to make sauces, dressings, and dairy products, to maintain quality and consistency.

Cosmetics:

Essential for mixing oils, dates, and other cosmetic compositions, to ensure consistency and consistency.

Agriculture:

Used to make fertilizers and pesticides to ensure even distribution of ingredients.

The integration of our mixers

Maintenance & Reliability

The Advantages

Bottom-entry mixers of Padmatch Industries have many advantages.

Efficiency:

Designed for efficiency, our mixers ensure fast and thorough mixing, reducing processing time.

Customization:

We offer custom mixer configurations to provide a customized solution that meets the unique requirements of your project.

Energy efficiency:

Our machines are designed to optimize energy consumption, save you money, and reduce your impact on the environment.

Made with high-quality materials and advanced technology, our mixers ensure reliable performance and a long service life.

The Conclusion

- Product Features

- Product Specifications

-

Easy loading and unloading

Easy loading and unloading -

Minimize equipment cost

Minimize equipment cost -

Minimize operating cost

Minimize operating cost -

Zero dead stock of liquid

Zero dead stock of liquid

Capacity

100 Ltr to 25000 Ltr per Batch

Material of Construction

SS 304 / SS 316

Dimensions

Customize

Warranty

1 year