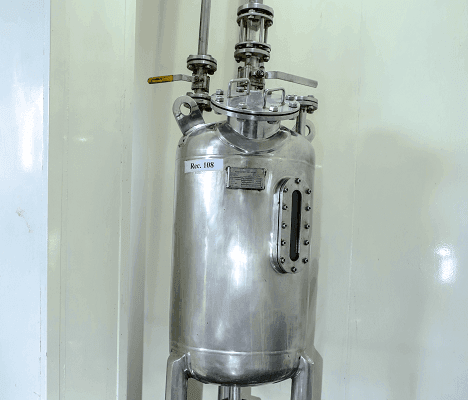

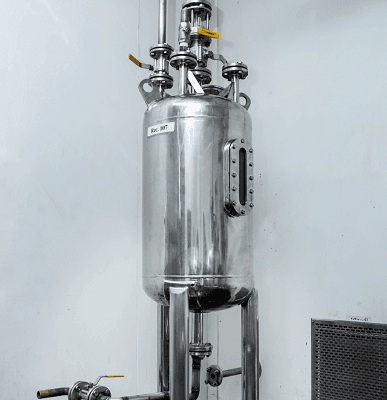

Chemical Receiver Tank

Chemical Receiver Tank

Many industries require a chemical receiver tank to store chemicals, solvents, and various types of liquids required for the processing of finished products. Padmatech Industries is a leading chemical receiver tank manufacturer based in Pune. We use top-quality stainless steel material for chemical receiver tank design and deliver the same within committed deadlines. Many of our clients are from the chemical and pharmaceutical industries and thus we are a highly recommended manufacturer of chemical receiver tanks for chemical plants and chemical receiver tanks for a pharmaceutical plant.

We are ISO 9001:2015 certified company and thus manufacture all our equipment in accordance with international standards. We are market leaders for chemical receiver tank suppliers for more than 20 years. We are also working for many international clients under various industry segments and thus gain a reputation as a trusted chemical receiver tank exporter.

Intended Usage

Chemical receiver tanks are fundamental for briefly storing and transferring chemicals during production processes. Our tanks are made from great materials like stainless steel, which gives incredible protection from corrosion, ensuring the safe containment of aggressive and reactive substances. This toughness is critical for keeping up with the integrity of the stored chemicals and forestalling contamination.

Manufacturing

Versatility

Maintenance and Low Energy Consumption

Energy proficiency is a part of the building design for our tanks. By incorporating sturdy materials and thermal management systems, our tanks help restrict energy consumption during chemical storage. This energy efficiency reduces operational expenses as well as lines up with modern economic practices.

Summary

- Product Features

- Product Specifications

-

Quality Material

Quality Material -

Rugged Design

Rugged Design -

High resistance to corrosion

High resistance to corrosion -

Low maintenance

Low maintenance -

Customized design as per site conditions

Customized design as per site conditions

Capacity

50 Ltr to 50000 Ltr

Material of Construction

SS304, SS316, SS316L, exotic alloy, Duplex 2205,SMO254, MS, CS, CS+, Hastelloy C276, B2,B3, Monel 400, 904 L, Alloy 20 Rubber lined, Titanium, Hast alloy, Nickel etc

Max Design Pressure

Full Vacuum

Warranty

1 year