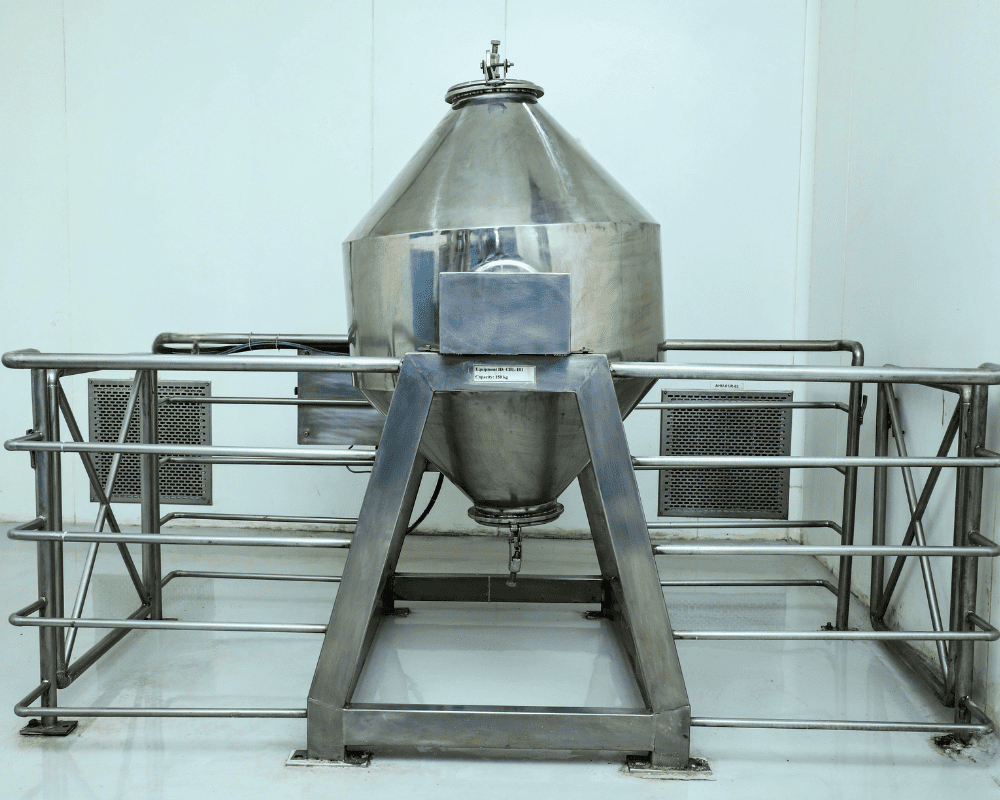

Double Cone Blender

Double Cone Blender Machine

Dry blending of free-flowing solids is a common task in many industries like pharmaceuticals, chemicals, food & beverage, fertilizers, plastics, nutraceuticals, pesticides, and cosmetics. double cone blender is the most efficient and widely used industrial equipment for mixing dry powders and granules. At Padmatech Industries, we have been at the forefront of stainless steel double cone blender manufacturing for over 20 years, specializing in the design and manufacture of customized double cone blenders depending on bulk density and percentage of the total mixture.

We are an ISO 9001:2015 certified company, ensuring that all blending equipment is manufactured using top-quality stainless steel material. As market leaders in turnkey and EPC projects, we also manufacture and supply a wide range of blending products, including:

-

Ribbon blenderRibbon blender

-

Paddle blenderPaddle blender

-

Octagonal Blender

-

V cone blender

-

Y cone blender

-

Spiral Blender

Working Principle of Double Cone Blender

A cone blender is used to produce homogeneous solid mixtures. It can perform homogeneous mixing of dry granules that require low shear forces, free-flowing powders, and the mixing and blending of particles with rapid mixing of particles regardless of various specific gravities. The material is fed into the drum of the double-cone blender.

Engineering of Double Cone Mixer Blender

Design and Development of Dual Cone Blender

Key Features of Cone Blender Machine

Cone blenders can produce consistent mixtures even when the amount of ingredients varies. This mixer also uses less energy than its agitator counterparts, is easy to load and unload, and has a hygienic design. The construction of the double-shell blender facilitates the thorough loading and discharge of materials. The double-cone shape at each end of the blender also allows for reliable powder discharge and homogeneous blending.

The timer function allows for quick functionality and increased accuracy. The cone shape and multi-sliding plate design make it easy to discharge residual material. More paddle-shaped baffles can be added to the machine to improve blending.

-

Product Features

-

Product Specifications

-

Uniform Mixing

-

Suitable Size of Butterfly Valve for Easy Discharge

-

Easy Cleaning & Operate

-

Low Maintenance

-

Highly Work Efficiently

-

Low Fuel Consumption

-

Incorporated with Liquid Dispensers and Lump Breakers

Capacity

5 Liters and 5000 Liters

Material of Construction

SS 304, SS 316

Dimensions

Customize

Warranty

1 year