Cryogenic Reactor

Cryogenic Reactor Manufacturer

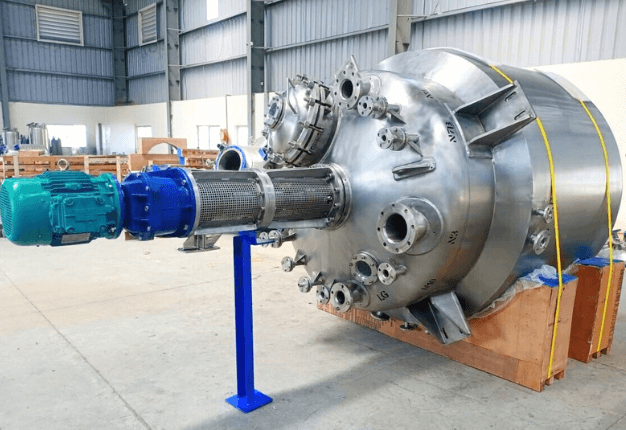

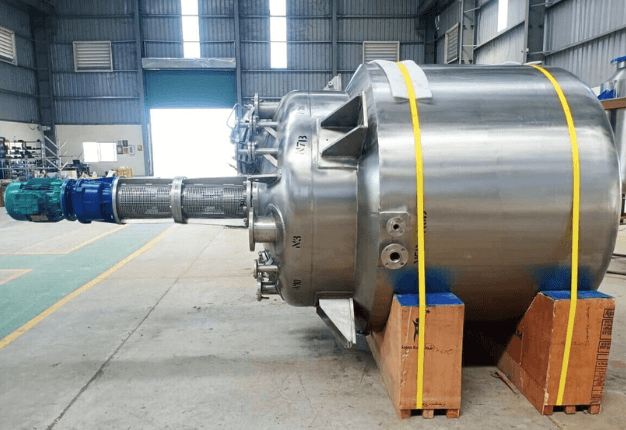

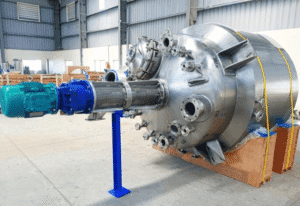

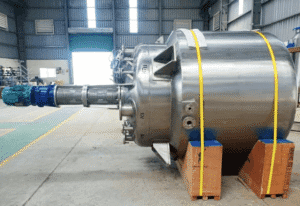

Padmatech Industries has been a trusted cryogenic reactor manufacturer in India for over 20 years. Cryogenic reactors are usually used for the chemical reaction of two or more chemicals. We are leading manufacturers of cryogenic containers, which enable high-speed reactions at -200°C. As an ISO 9001:2015 certified company, we use high-grade raw materials sourced from reliable vendors. Our cryogenic vessels are designed to safely store materials at temperatures below -200°C

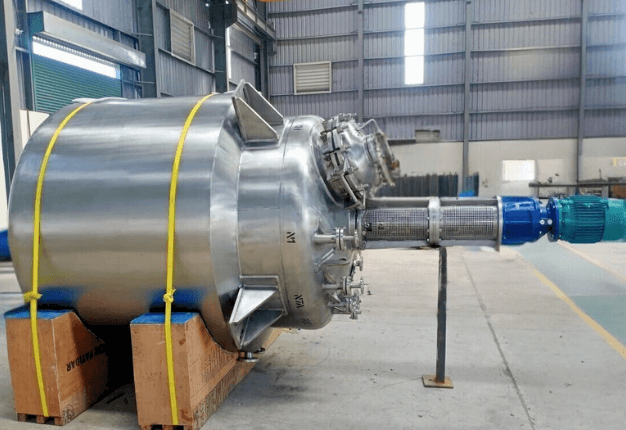

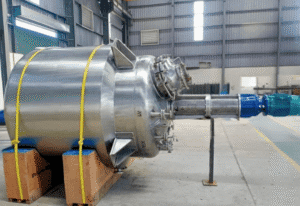

We are also a leading high pressure reactor manufacturer, thanks to our ability to deliver your product on time and within the committed deadline. Our expert team of designers and fabricators can manufacture single-, double-, or triple-wall dewars to provide the best insulation for your specific requirements. Based on the respective industry and project needs, we also design custom cryogenic storage tanks. Chemical handling applications particularly benefit from our cryogenic reactors, as they require extremely low temperatures to ensure the security and efficiency of reactions. These cryogenic reactors are essential in industries

like pharmaceuticals, petrochemicals, and materials science, where exact temperature control is paramount. At the core of Padmatech Industries’ cryogenic reactors lies state-of-the-art technology designed to withstand the challenges of extreme cold. These reactors are engineered to operate efficiently at temperatures as low as –200°C, making them ideal for processes involving condensed gases like liquid nitrogen and liquid helium. The use of cryogenic temperatures enables the execution of chemical reactions essential for the synthesis of high-value compounds or the stabilization of reactive intermediates.

Advantages of Our Cryogenic Reactor for Industrial Applications

1. Robust Construction:

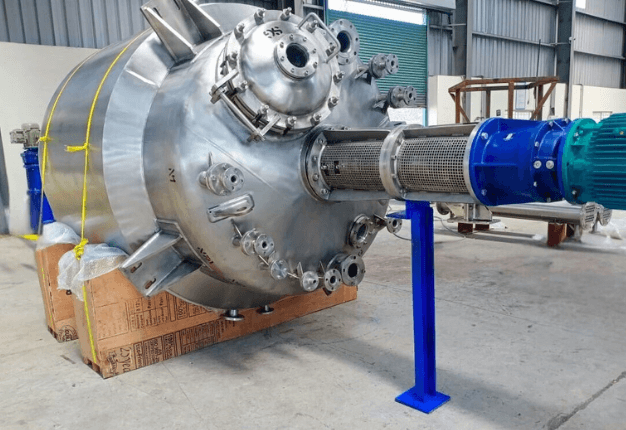

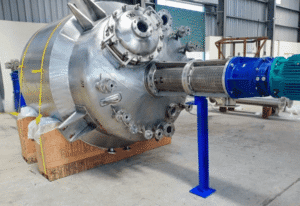

Made from high-quality materials like stainless steel, hastelloy, cupronickel, inconel and titanium, Padmatech’s cryogenic reactors ensure strength and protection against the unforgiving conditions of cryogenic cycles. The robust construction limits the risk of material fatigue and guarantees long-term dependability.

2. Advanced Insulation:

Effective insulation is essential for maintaining cryogenic temperatures. Padmatech reactors incorporate multifaceted insulation frameworks to limit heat ingress and enhance thermal efficiency. This best-in-class insulation helps in maintaining the ideal temperature for extended periods, thereby ensuring process stability.

3. Precise Temperature Control:

Temperature control is a critical part of cryogenic processes. Padmatech’s reactors are equipped with cutting-edge temperature monitoring and control systems. These systems respond to fluctuations and maintain optimal reaction conditions, which is essential for achieving consistent and high-quality results.

4. Safety Features:

Handling cryogenic substances involves significant risks. Padmatech’s reactors are designed with multiple safety features, including pressure relief valves, emergency shutdown systems, and comprehensive monitoring capabilities to ensure safe operation under all conditions.

5. Customization:

Knowing that different applications have different requirements, we offer customized cryogenic reactors. Clients can choose reactor size and extra accessories to meet their particular needs.

Applications of Our Cryogenic Reactors

Our reactors are used across different sectors. In the drug business, they are utilized for combining highly pure compounds and balancing out sensitive intermediates. In petrochemicals, cryogenic reactors work with the creation of particular polymers and materials with upgraded properties. Moreover, these reactors are utilized in innovative work for concentrating on response systems at low temperatures and growing new materials.

Cryogenic Reactors Built for Complex Industrial Needs

At the centre of Padmatech Industries’ cryogenic reactors is state-of-the-art technology intended to deal with the difficulties of outrageous coldness. These reactors are designed to work productively at temperatures as low as – 200°C, making them ideal for processes including condensed gases like liquid nitrogen and liquid helium. The use of cryogenic temperatures empowers the execution of chemical reactions, which are important for the amalgamation of highly valuable items or the adjustment of receptive intermediates.

-

Product Features of Cryogenic Reactor

-

Product Specifications of Cryogenic Reactor

-

Easy To Use

Easy To Use -

High Efficiency

High Efficiency -

Optimum Storage Capacity

Optimum Storage Capacity -

Available in High and Low Pressure Models

Available in High and Low Pressure Models

Capacity

250 Ltr to 60,000 Ltr

Material of Construction

Stainless Steel, Hastelloy, Cupronickel, Inconel, Titanium

Max Design Pressure

25 Bar

Warranty

1 year

Contact Padmatech Industries for world-class process equipment to boost your business & productivity.

Contact Padmatech Industries for world-class process equipment to boost your business & productivity.