MEE & ZLD Plant

We are turnkey suppliers for providing perfect solutions for multiple-effect evaporators (MEE) and zero liquid discharge (ZLD) Plant systems in various fields like Chemicals, Paper & pulp, Food & pharmaceuticals, Alcohol plants, Brewery plants, Oil industries etc. Our MEE (Multiple effect Evaporators) designs are customised to a greater extent to make it satisfactory to our customers. A suitable system is designed based on the composition of the effluent to be treated. We design & deliver considering every plant design as per requirements. Our projects are customised for the specific requirements of our various customers.

We are proud to deliver environment-friendly solutions that help the Green & clean environment criterion. We commit ourselves as the highest utility-saving design company operating in this field. In most of the cases end product is in solid powder form which is easy to dispose of. The recovered solvent is stored separately, purified to the desired concentration & recycled back into the process. The liquid obtained after evaporation is mainly clear water. This can be recycled in a process plant for reuse

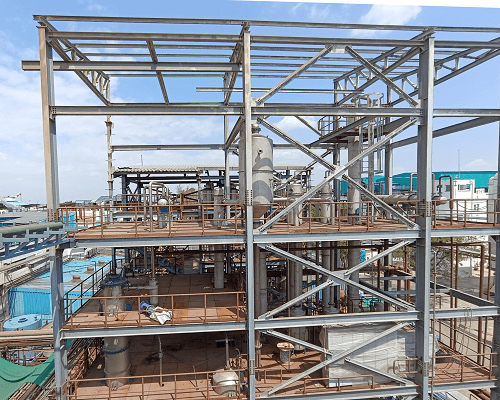

We successfully dispatched MEE and ZLD Plant To Our Customer

A 75 KLPD multi-effect evaporator is a system used to concentrate solutions in wastewater treatment and food processing. This utilizes multiple stages to evaporate water using the steam produced. By recycling heat, the MEE decreases costs and environmental impact, making it an ideal solution for large-scale industrial applications that require high-capacity and energy-efficient water evaporation process.

MEE Plant

Padmatech Industries’ multi-effect evaporator plants are developed to provide solutions for a variety of applications. These plants are designed to handle huge evaporation needs, making them ideal for water treatment, food processing, and chemical manufacturing. Padmatech’s systems increase the utilization of thermal energy, significantly reducing operational costs and environmental footprint.

Our MEE plant is developed for performance and durability. The plants are designed using materials that can withstand harsh industrial environments and corrosive substances. Padmatech ensures that each system delivers the highest levels of efficiency and productivity.

Our multi-effect evaporator plants incorporate advanced technology and design principles, ensuring minimal energy consumption and maximum recovery of valuable resources.

Our multi-effect evaporator plants incorporate advanced technology and design principles, ensuring minimal energy consumption and maximum recovery of valuable resources.

Our 10 KLPD (Kilo Liters Per Day) capacity multi-effect evaporator is an advanced and efficient solution designed for evaporation needs. This employs the principle of multi-effect evaporation, which utilizes the vapour generated in one effect as the heating medium for the next, thereby significantly reducing overall energy consumption. This use of energy makes the process not only cost-effective but also environmentally friendly, as it maximizes the use of available thermal energy.

Padmatech’s multi-effect evaporator is engineered to handle high-capacity operations with precision and reliability. It is constructed with robust materials to ensure durability and longevity, even under continuous use in demanding industrial environments. The system focuses on decreasing costs while increasing final output, making it ideal for pharmaceutical, chemical, and wastewater treatment industries.

Padmatech’s multi-effect evaporator is engineered to handle high-capacity operations with precision and reliability. It is constructed with robust materials to ensure durability and longevity, even under continuous use in demanding industrial environments. The system focuses on decreasing costs while increasing final output, making it ideal for pharmaceutical, chemical, and wastewater treatment industries.

The advantage of our 10 KLPD multi-effect evaporator is its ability to maintain a high level of performance with low maintenance. Our MEE’s controls and features allow easy operation. Our evaporator can be managed with low manual intervention, reducing downtime and costs. Our MEE also decreases waste, promoting sustainability.

10 KLPD capacity MEE is a major development in the industrial evaporation sector. Its efficiency makes it a must-have for those who are looking to improve their evaporation process.

10 KLPD capacity MEE is a major development in the industrial evaporation sector. Its efficiency makes it a must-have for those who are looking to improve their evaporation process.

Our MEE And ZLD Plant Features

-

We deliver plants as fully automatic or Semi-automatic or Manual operation with ease in operation as per customer requirement

-

With complete mechanical & electrical installation in-house facility

-

Quick service to our customers even after execution & warranty/ guarantee period over

-

Our Plants are always designed considering future expansion requirements also.

-

Minimum operation & investment cost for customers

-

Plant operation costs are very low.

-

Skid-mounted unit for small-capacity plants

-

Highest condensate & heat recovery

-

Highest utility saver designs

-

Easy to operate & Compact Layout