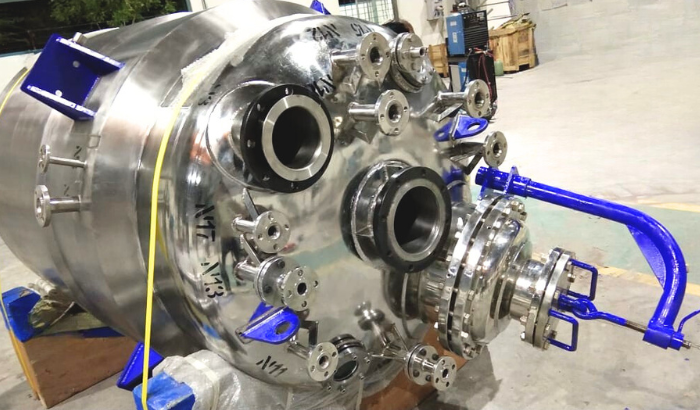

Stainless Steel Reactor

SS Reactor Manufacturer

Padmatech Industries has been a leading manufacturer of stainless steel reactors for over 20 years. We know the exact importance of these reactors for chemical plants, and thus we manufacture them using quality materials. We are an ISO 9001:2015 certified company. These SS reactors are essential equipment for industries of any size involved in chemical processing. Thus, we manufacture custom-built stainless steel reactors as per industry requirements. We have an experienced and qualified team to take care of your reactor design as per your project requirements.

We are a leading stainless steel reactor supplier in India on a turnkey basis. We have good relations with many reputable industries. We have also installed our stainless steel reactors at the sites of our esteemed customers abroad, and thus we are also recognized as a leading exporter. We deal in high-quality chemical and industrial equipment, which has gained fame for its state-of-the-art stainless steel reactor.

These reactors are fundamental in a variety of industries, including pharmaceuticals, chemicals, food processing, drugs, and materials science, where exact control of reaction conditions is critical. Our stainless steel reactor works with reactions under low-pressure conditions, providing benefits in terms of efficiency, product quality, and safety.

Stainless Steel Reactor Working Principle

Our reactors operate in a low-pressure environment inside the reaction chamber. This reduction in pressure can fundamentally bring down the limits of solvents and reactants, enabling reactions to occur at lower temperatures than would be conceivable under normal atmospheric conditions. It is useful for heat-sensitive materials, as it prevents thermal degradation and preserves the integrity of delicate compounds. By keeping in a vacuum, these reactors likewise limit the presence of air and moisture, which can hinder certain reactions, especially with highly reactive or hygroscopic materials.

Advantages of Stainless Steel Reactor

An important advantage of Padmatech’s stainless steel reactor is its ability to increase reaction productivity and output. Working in vacuum conditions, these reactors can speed up the reaction rates and work on large-scale exchange, which leads to a high yield of the desired goods.

Trendsetting is a sign of our stainless steel reactor. They are outfitted with refined vacuum siphons and control frameworks that take into consideration the exact guidelines of pressure inside the reactor. This degree of control is essential for keeping up with the ideal circumstances for every particular reaction. Our reactors are equipped with accurate sensors and monitoring equipment that give information on key details like pressure, temperature, and vacuum levels. These details are for experts, permitting them to adjust the reaction conditions to accomplish ideal results.

Safety Features in SS Reactor

Safety is the most important concern in the plan of our reactor design. The reactors incorporate different well-being highlights to safeguard both the equipment and the workers. These highlights incorporate vacuum relief valves, pressure sensors, and automatic shutdown systems that act in case of a pressure or temperature trip. The plan likewise consolidates safeguards to forestall the tainting of the reaction climate, which is fundamental for keeping up with item immaculateness, particularly in drug and food handling applications.

Customizable Stainless Steel Reactors for Industrial Needs

One component of our reactors is their ability to adapt. They’re built to serve a variety of reactions, from small to large industrial reactions. Our reactors offer the adaptability and quality to satisfy different needs.

Our organization provides continuous help so that our clients can expand the exhibition and advantages of their stainless steel reactor. This consumer loyalty highlights our devotion to greatness and its job as a confided-in accomplice in the industrial and chemical equipment sector.

Reliable and Efficient Stainless Steel Reactor

Overall, the stainless steel reactor of Padmetech Industries reaches the pinnacle of design and development in the field of chemical and industrial equipment. Our strong development, trend-setting innovation, and safety features make our reactors essential equipment for industries seeking high-performance processing capabilities. These reactors are a demonstration of our responsibility to provide high-quality solutions that bring productivity, sustainability, and innovation to industrial operations.

-

Stainless Steel Reactor Product Features

-

Stainless Steel Reactor Specifications

-

Low Operating Cost

Low Operating Cost -

High Efficiency

High Efficiency -

Maintenance free long term operations

Maintenance free long term operations -

High durability against corrosive solvents

High durability against corrosive solvents -

Vacuum Trap Provision / Vacuum Breaker

Vacuum Trap Provision / Vacuum Breaker

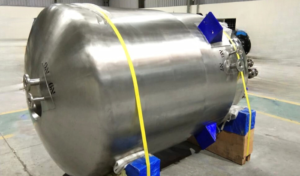

Capacity

100 Ltr to 50000 Ltr

Max Design Pressure

Full Vacuum

Automation Type

Manual / Semi Automation / Automation

Warranty

1 Year

Contact Padmatech Industries for world-class process equipment to boost your business & productivity.

Contact Padmatech Industries for world-class process equipment to boost your business & productivity.