Twin Shaft Mixer

Twin Shaft Mixer

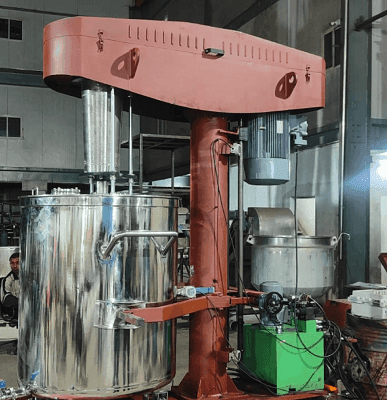

Many industries deal with the processing of high viscosity mixing situations wherein Twin Shaft Mixer plays a vital role to deliver the desired quality output on time and within budget. Padmatech industries are leading twin shaft mixer manufacturers using the best quality stainless steel materials. Our twin-shaft mixers consist of a high-speed disperser and a low-speed anchor scraper allowing both agitators to operate independently managing any variation of speed. We are working with many reputed industries in and around Pune and thus emerged as trusted twin-shaft mixer suppliers. This application is mainly a combination of a tooth saw and butterfly impeller.

We have a team of highly experienced and qualified workers and thus are capable of manufacturing customize equipments of following types:

• Paddle mixer

• Industrial mixer

• Rotary mixer

• Ribbon blender

• Dual shaft mixer

• High speed mixer

• Powder mixer machine

• Vertical mixer

• Horizontal mixer

• Powder blender equipment

• Industrial powder mixer

• Drum mixers

Plan & Operation

Development & components

Applications Across Various Sectors

Chemical Processing: Our twin shaft blenders can easily handle the mixing of multiple chemical compounds, guaranteeing consistency in items such as adhesives, sealants, and tars.Their strong construction design helps during the harsh conditions of chemical processing situations.

Food Industry: Our twin shaft mixers are used to blend ingredients like dough, batter, and confectionery.The mixers guarantee a consistent blend.

Proficiency & Execution

Maintenance & Reliability

Conclusion

- Product Features

- Product Specifications

-

Drum locating and centering device.

Drum locating and centering device. -

Clamping device for the tub.

Clamping device for the tub. -

Hydraulic up and down, maintenance-free application.

Hydraulic up and down, maintenance-free application. -

Special spinal bearing use

Special spinal bearing use -

High precision machining is done in such a way that a running shaft cannot be distinguished from a static one

High precision machining is done in such a way that a running shaft cannot be distinguished from a static one -

Noise Free

Noise Free -

Twin shaft maximum speed – 100 R.P.M

Twin shaft maximum speed – 100 R.P.M -

Tooth a saw type impeller Mixer maximum speed – 2900 R.P.M

Tooth a saw type impeller Mixer maximum speed – 2900 R.P.M

Capacity

100 Ltr to 5000 Ltr per Batch

Material of Construction

SS 304 / SS 316

Dimensions

Customize

Warranty

1 year