Unit III

Unit III is located at Newasa Industrial area, Ahemadnager and is the flagship of Padmatech Industries. This 80,000-square-foot unit is dedicated to high-volume production and innovative design solutions. The 12-meter height is ideal for the placement of extensive production lines and advanced industrial equipment. Powered by a significant 100 HP power supply, Unit III is equipped to handle large production volumes with remarkable efficiency. The large plot area allows different production processes to be combined under one roof, which promotes synergy and unity of operations. This huge space facilitates the seamless integration of various manufacturing stages, from raw material processing to the final product, increasing efficiency and reducing production time.

Advanced EPC Project Manufacturing in Unit-3

Precision Welding

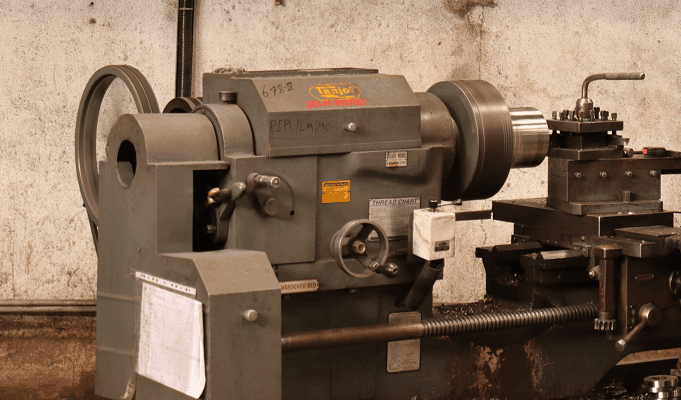

Cutting-Edge Machinery

Commitment to Excellence