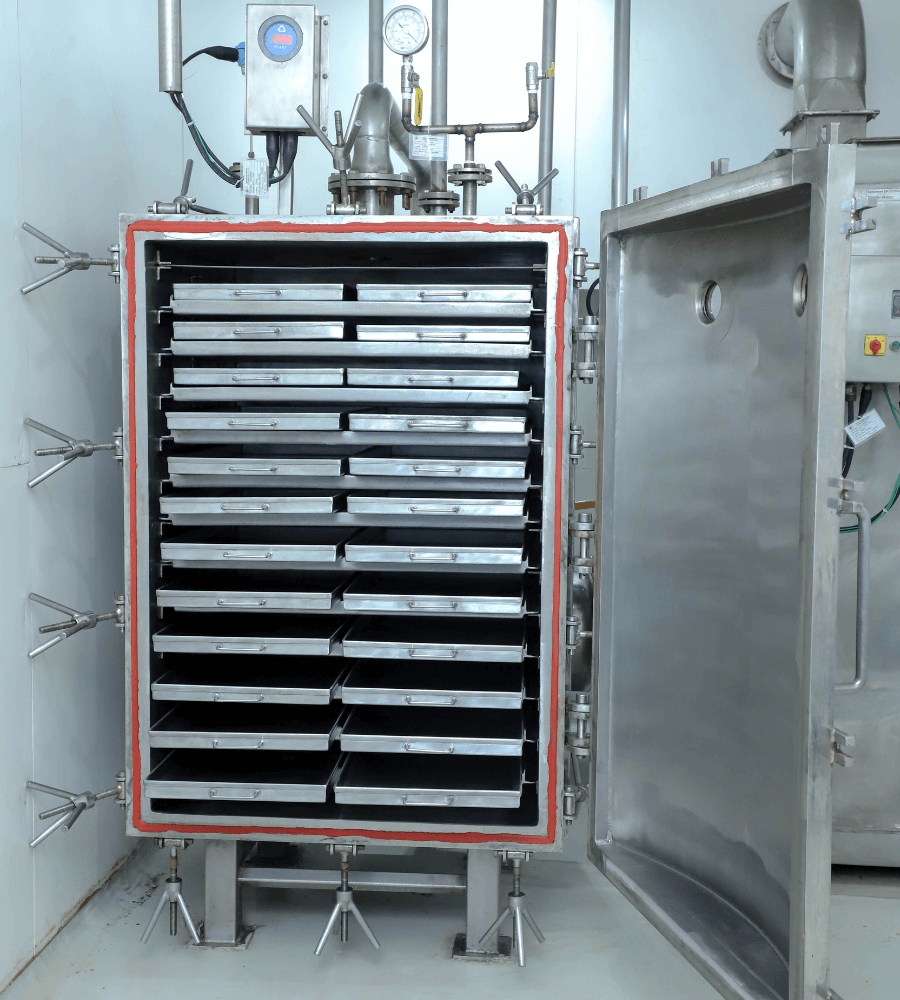

Vacuum Tray Dryer

Vacuum Tray Dryer Manufacturer

Removal of wet solids by creating a vacuum through the mass transfer method is known as vacuum drying. The vacuum tray dryer is the primary equipment used in this process. A vacuum dryer is primarily used for processing food products, electronic components, and various machined parts. Padmatech Industries has been a leading manufacturer of vacuum drying machine for over 20 years. We are pioneers in the manufacturing of tray dryers, rotary dryers, drying ovens, industrial dryers, spray dryers, and drum dryers. As an ISO 9001:2015 certified company, we ensure that all our vacuum drying equipment is of the highest quality.

We are a leading vacuum tray dryer supplier to the chemical, pharmaceutical, and food industries. With a strong customer base outside India, we also serve as a trusted exporter of vacuum tray dryers. Our custom trays are manufactured to meet specific project requirements, ensuring flexibility and precision. Our high-quality vacuum tray dryers cater to the diverse needs of various industries. They are specifically designed for heat-sensitive materials and products that require low-temperature drying. The system operates by creating a low-pressure environment, which significantly reduces the boiling point of water and other solvents. This enables efficient moisture removal at lower temperatures, helping preserve the quality and integrity of delicate materials.

Working Principle of Vacuum Tray Dryer

The functioning rule of our vacuum tray dryer includes putting the wet material on trays inside a drying chamber. When the chamber is closed, a vacuum pump decreases the internal pressure, and heat is applied to the trays through conduction, frequently facilitated by heated shelves. The reduced pressure lowers the boiling point of the moisture inside the material, allowing it to dissipate at significantly lower temperatures than it would under atmospheric conditions. The vacuum pump then removes the moisture from the chamber, ensuring an intensive drying process.

Benefits of Industrial Vacuum Tray Dryers

Our vacuum tray dryers offer several key benefits. Firstly, they are ideal for drying heat-sensitive materials like biological products and certain chemicals, where high temperatures could cause degradation or loss of efficacy. This ensures that these items don’t lose their properties. Moreover, the vacuum environment minimizes the risk of oxidation and contamination, further protecting product integrity.

Vacuum Tray Dryer Design

Another major advantage is the uniform drying achieved across all trays. Our high-quality design ensures consistent heat distribution, resulting in uniform moisture removal from all parts of the material. This is especially important in industries where product consistency and quality are paramount. The efficiency of vacuum drying also leads to shorter drying times compared to conventional methods, improving efficiency and throughput for industrial operations.

Energy Efficiency in Vacuum Tray Dryer Systems

Padmatech Industries’ Industrial vacuum tray dryers are also designed with energy efficiency in mind. By using lower temperatures and reducing drying times, our systems help monitor energy consumption and minimize operational expenses. The robust construction and use of high-quality materials guarantee durability and longevity, furnishing our clients with dependable and long-lasting equipment.

Why Choose Padmatech Industries for Tray Dryers?

They are ideal for sensitive and high-value products. Their capacity to operate at low temperatures while maintaining product quality, combined with uniform drying and energy efficiency, makes them must-have equipment across different industries. By continuing to enhance and refine our drying solutions, we remain focused on meeting the evolving needs of our clients and supporting their success in a highly competitive marketplace.

Product Features

Product Specifications

Requires Minimum Power Input

Requires Minimum Power Input Optimized for maximize discharge during emptying

Optimized for maximize discharge during emptying Bear high vacuum pressure

Bear high vacuum pressure High Durable

High Durable Energy Efficient Model

Energy Efficient Model Easy to Operation

Easy to Operation

Capacity

12/24/36/48/96 Tray

Material of Construction

SS316 / SS 304

Max Design Pressure

Full Vacuum

Model

Addition Limpet Coil Model is also available / PLC HMT will be provided

Warranty

1 year

Contact Padmatech Industries for world-class process equipment to boost your business & productivity.

Contact Padmatech Industries for world-class process equipment to boost your business & productivity.